Assembly Solution

- In-house Machining Centre

- Precision Tooling Jigs & Fixtures

- Testing & Inspection

- Material Handling

Jump to Products

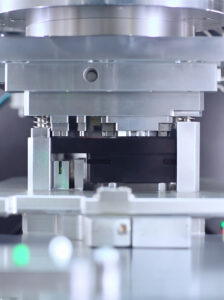

Press Application

Utilising controlled force to shape, assemble, test, or maintain components in manufacturing and mechanical processes.

- Intelligent Servo Press

- Hydraulic Press

- Pneumatic Press

Robot & Gantry

Automating precise, repetitive tasks such as material handling, assembly, and machining, improving efficiency, accuracy, and safety in production processes.

- Articulated Robot

- SCARA Robot

- Collaborative Robot

- XYZ Cartesian Robot

- Pneumatic Arm with End Effector

- Quick-Change End Effector

Testers

Evaluating the performance, functionality, or quality of components, systems, or materials to ensure they meet required specifications and standards.

- Leak Test

- Electronic Test

- Conductive Test

- Functional Test

- EOL Test

- Motor Test

- Axial Play Check

Welding

Connecting two or more metal or thermoplastic parts by applying heat, pressure, or both to form a strong, durable bond.

- Metal Laser Welding

- Plastic Laser Welding

- Ultrasonic Welding

- Resistance Welding

Conveyance

Transferring materials, components, or products from one location to another within a manufacturing or processing environment.

- Belt Conveyor

- Motorized Roller Conveyor

- Class 10 Clean Room Roller Conveyor

- Chain Conveyor

- Monorail Conveyor

- High Precision Cam Driven

- Magnetic Driven Linear Conveyance

Vision & Measurement

Inspecting the dimensions, quality, and positioning of parts or products with high precision and speed.

- Distance Measurement

- Thickness Measurement

- Line Scan Laser Profiler

- 3D Laser Profiler

- Vision Inspection

- Vision Calibration

- Vision Identification

- Vision Guided Motion

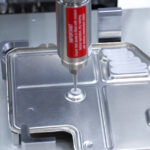

Dispensing

Applying controlled amounts of liquids, adhesives, lubricants, or other materials onto specific areas during manufacturing or assembly processes with high accuracy and repeatability.

- Grease Dispenser

- Oil Dispenser

- Liquid Dispenser

- Adhesive Dispenser

- Thermal Compound Dispenser

Feeder

Automatically supply parts, components, or materials to machines or assembly lines in the required orientation, ensuring continuous and efficient production flow.

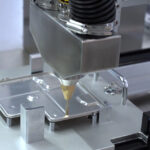

Screwdriving

Fastening components together for automated or manual assembly processes to ensure secure and precise connections.

Plasma Treatment

Modifying the surface properties of materials, such as improving adhesion or cleanliness.

Buffer & Storage

Temporarily hold and store materials, components, or products between process steps, ensuring smooth workflow and reduce downtime in production

Labeling & Marking

Provide information on parts or products through printed labels, codes or direct markings for quality control and traceability.

Electrical Assembly

Connect and integrate electrical components, such as wires, connectors, drivers and circuit breakers, into functional systems or devices.

- Wire Harness

- Control Boxes

Jump to Products

Press Application

Enhance precision, efficiency, and reliability with our advanced press systems tailored for various industrial applications.

- Intelligent Servo Press – Delivers high-precision force control and real-time monitoring for superior performance.

- Hydraulic Press – Provides powerful and consistent force, ideal for heavy-duty pressing and forming applications.

- Pneumatic Press – A cost-effective and efficient solution for light to medium-duty pressing tasks.

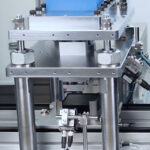

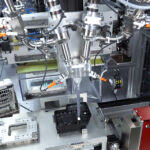

Robot & Gantry

Optimize automation with our advanced robotic and gantry systems designed for precision, efficiency, and flexibility in industrial applications.

- Articulated Robot – Multi-jointed robotic arms for high flexibility and complex tasks.

- SCARA Robot – Ideal for high-speed, precise pick-and-place operations.

- Collaborative Robot – Safe and adaptable robots for human-robot interaction.

- XYZ Cartesian Robot – Linear motion robots for precision positioning and automation.

- Pneumatic Arm with End Effector – Versatile robotic arm powered by pneumatic control.

- Quick-Change End Effector – Enables fast and efficient tool switching for multi-tasking operations.

Testers

Ensure product quality, performance, and reliability with our advanced testing solutions tailored for various industrial applications.

- Leak Test – Detects leaks and ensures airtight sealing in components.

- Electronic Test – Verifies electrical functionality and circuit integrity.

- Conductive Test – Assesses material conductivity for optimal performance.

- Functional Test – Evaluates overall system operation under real-world conditions.

- EOL Test (End-of-Line Test) – Final quality check before product release.

- Motor Test – Measures motor efficiency, torque, and durability.

- Axial Play Check – Ensures precise mechanical alignment and minimal shaft movement.

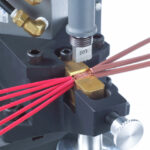

Welding

Achieve precision, strength, and efficiency with our cutting-edge welding technologies for various industrial applications.

- Metal Laser Welding – Delivers high-precision, strong, and clean welds for metal components.

- Plastic Laser Welding – Ensures seamless, high-strength joints in plastic materials with minimal thermal stress.

- Ultrasonic Welding – A fast and reliable method for joining thermoplastics and thin metals without adhesives or fasteners.

- Resistance Welding – Uses electrical current and pressure for strong and durable metal welds.

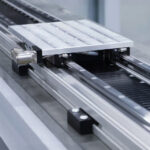

Conveyance

Enhance material handling efficiency with our advanced conveyance systems, designed for precision, reliability, and seamless automation.

- Belt Conveyor – Ideal for continuous transport of materials with smooth and efficient operation.

- Motorized Roller Conveyor – Energy-efficient and modular design for automated material movement.

- Class 10 Clean Room Roller Conveyor – Designed for ultra-clean environments with minimal contamination.

- Chain Conveyor – Heavy-duty solution for transporting bulky or irregular-shaped items.

- Monorail Conveyor – Overhead transport system for space optimization and workflow efficiency.

- High Precision Cam Driven – Ensures synchronized and accurate material movement.

- Magnetic Driven Linear Conveyance – Provides contactless, high-speed, and precise positioning.

Vision & Measurement

Vision & Measurement technologies integrate optical systems and advanced software to enhance precision, automate processes, and ensure high-quality output in industries like manufacturing and inspection. These systems use cameras, lasers, and sensors to measure, inspect, and guide motion with great accuracy.

- Distance Measurement – Measures the space between two points using optical or laser sensors for precise positioning in various applications.

- Thickness Measurement – Determines the thickness of materials using sensors or lasers, ensuring consistency and quality control.

- Line Scan Laser Profiler – DCaptures 2D surface profiles using a laser line, ideal for high-speed surface inspection and quality control.

- 3D Laser Profiler – Creates detailed 3D surface models using laser triangulation or structured light for accurate geometry measurements.

- Vision Inspection – Uses cameras and image processing to inspect products for defects, ensuring they meet quality standards.

- Vision Calibration – Optimizes vision systems to ensure accurate measurements by correcting optical distortions and aligning cameras.

- Vision Identification – Identifies, tracks, or authenticates objects through visual features like OCR, barcode reading, or pattern recognition.

- Vision Guided Motion – Combines vision with robotic motion to enable real-time object identification and precise task execution, such as picking or placing.

Dispensing

Dispensing refers to the precise application of materials like liquids, lubricants, or adhesives in manufacturing and assembly processes.

- Grease Dispenser – Applies grease for lubrication in mechanical systems, reducing friction and wear.

- Oil Dispenser – Dispenses oil for lubrication in machines, ensuring smooth operation.

- Liquid Dispenser – Precisely dispenses liquids (e.g., water or chemicals) for various industrial applications.

- Adhesive Dispenser – Applies adhesives for bonding surfaces in assembly lines.

- Thermal Compound Dispenser – Applies thermal paste to enhance heat transfer in electronics.

Feeder

A feeder automatically supplies materials or components to a production line, ensuring a smooth and continuous flow for efficient manufacturing.

Screwdriving

Screwdriving is the automated or manual process of driving screws into materials for precise and consistent fastening.

Plasma Treatment

Plasma treatment uses ionized gas to enhance surface properties for better adhesion and coating.

Buffer & Storage

Buffer & Storage temporarily holds materials or data to ensure smooth workflow in production or management.

Labeling & Marking

Labeling & Marking applies labels or markings for product identification and tracking.

Electrical Assembly

Electrical Assembly involves the process of assembling electrical components, such as wires, circuits, and control systems, into functional units for use in various devices and machinery.

- Wire Harness – A wire harness is a group of wires bundled together and used to transmit electrical signals or power between components in machines or vehicles.

- Control Boxes – ontrol boxes house electrical components and circuits that manage and control systems or machinery, providing protection and organization for wiring and controls.

Press Application

Utilising controlled force to shape, assemble, test, or maintain components in manufacturing and mechanical processes.

- Intelligent Servo Press

- Hydraulic Press

- Pneumatic Press

Robot & Gantry

Automating precise, repetitive tasks such as material handling, assembly, and machining, improving efficiency, accuracy, and safety in production processes.

- Articulated Robot

- SCARA Robot

- Collaborative Robot

- XYZ Cartesian Robot

- Pneumatic Arm with End Effector

- Quick-Change End Effector

Testers

Evaluating the performance, functionality, or quality of components, systems, or materials to ensure they meet required specifications and standards.

- Leak Test

- Electronic Test

- Conductive Test

- Functional Test

- EOL Test

- Motor Test

- Axial Play Check

Welding

Connecting two or more metal or thermoplastic parts by applying heat, pressure, or both to form a strong, durable bond.

- Metal Laser Welding

- Plastic Laser Welding

- Ultrasonic Welding

- Resistance Welding

Conveyance

Transferring materials, components, or products from one location to another within a manufacturing or processing environment.

- Belt Conveyor

- Motorized Roller Conveyor

- Class 10 Clean Room Roller Conveyor

- Chain Conveyor

- Monorail Conveyor

- High Precision Cam Driven

- Magnetic Driven Linear Conveyance

Vision & Measurement

Inspecting the dimensions, quality, and positioning of parts or products with high precision and speed.

- Distance Measurement

- Thickness Measurement

- Line Scan Laser Profiler

- 3D Laser Profiler

- Vision Inspection

- Vision Calibration

- Vision Identification

- Vision Guided Motion

Dispensing

Applying controlled amounts of liquids, adhesives, lubricants, or other materials onto specific areas during manufacturing or assembly processes with high accuracy and repeatability.

- Grease Dispenser

- Oil Dispenser

- Liquid Dispenser

- Adhesive Dispenser

- Thermal Compound Dispenser

Feeder

Automatically supply parts, components, or materials to machines or assembly lines in the required orientation, ensuring continuous and efficient production flow.

Screwdriving

Fastening components together for automated or manual assembly processes to ensure secure and precise connections.

Plasma Treatment

Modifying the surface properties of materials, such as improving adhesion or cleanliness.

Buffer & Storage

Temporarily hold and store materials, components, or products between process steps, ensuring smooth workflow and reduce downtime in production

Labeling & Marking

Provide information on parts or products through printed labels, codes or direct markings for quality control and traceability.

Electrical Assembly

Connect and integrate electrical components, such as wires, connectors, drivers and circuit breakers, into functional systems or devices.

- Wire Harness

- Control Boxes